TURBOPUMPS: Speed matters...

TURBOPUMPS: Speed matters...

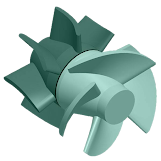

Have you seen a pump? A small water pump. It is used to push water from one tank to another. A rocket uses a very similar pump, with a hundred times more power than that. This pump is similar in dimensions but has supreme efficiency. This pump is known as the TURBOPUMP. While Rocket Engine is the heart of the rocket, similarly a TURBOPUMP is the heart of the Liquid Rocket Engine. It's a lot of Force in a Small Package. It is the most complex rocket engine part ever made with Additive Manufacturing. Nothing special about it, but a rocket engine's efficiency is purely dependent on the power of this beast. TEXTBOOK DEFINITION goes something like this: (Trust me it's BORING!)

"A TURBOPUMP is a propellant pump with two main components: a rotodynamic pump and a driving gas turbine, usually both mounted on the same shaft or sometimes geared together."

Don't worry, we'll reduce its complexity. Here we go!

Rocket Turbopumps are so complex that rocket scientists call their rockets fancy flying turbopumps. It is that complicated to design. Since 90% cost of the rocket is the cost of its rocket engine, 90% of the cost of a rocket engine is the cost of the turbopump.

If you take rocket propellants and say, I have understood rocket engines. NO! What you have is just a flame thrower. It will just generate heat after combustion. If you want that pressure or the thrust force, you need to throw out the propellant at a massive speed. And it's the job of this beast to produce that insane thrust force. Due to its tough engineering, it can top its optimal performance to be 70-90% efficient. The turbopump shaft rotates at an insane RPM which ranges from 30K to 95K.

Check out for updates by NASA: NASA's new 3D Printed Turbopump

To demonstrate how much fuel this beast consumes per second let's take an example of the godly RS-25 Engine. The turbopump of that engine consumed 952L of liquid hydrogen and 342L of liquid oxygen.

There are two types of turbopumps, a CENTRIFUGAL PUMP and an AXIAL-FLOW PUMP. Let's set the differences between them.

Centrifugal Pump:

It's similar to basic fluid pumps. Its working can be compared to the windmills. The gushing fluid (in our case, the pressurized propellant) rotates the shaft of the turbine at an insane angular velocity which in turn drives the pump. So basically it is a fuel-driven turbine. The rotating shaft is welded with a couple of spiral structures which acts to boost the fuel arriving from the tanks and direct it towards the combustion chamber.

Axial-Flow Pump:

There's a beautiful video on steam engines. Checkout here

That's a lot of technical knowledge. With that, I take a leave! Hey, it's Hardik, signing off.

That's a lot of technical knowledge. With that, I take a leave! Hey, it's Hardik, signing off.

Humourous, you would love it!! : Direct Link

Make sure you follow my Instagram page for regular updates: Direct Link

Speed matters and thats why you bust within 2 seconds, like the huge virgin you are, with your 2 cm micropenis.

ReplyDeleteThe only pump you know is how you pump elon's c*ck down your throat and let him cum cuz you are such a fucking beta ass dog.

ReplyDelete